A real Caulk - Up

To say nothing of a bit of a screw up. Spent the last two days doing that. Caulking all the nail holes and cracks and putting five pounds of 2 1/2 inch screws into the siding. When they built this place they didn't use ring shank nails only common 3 1/2 inch ones and they will easily pop out, so everywhere they used a nail I put a #10 outdoor rated robertson wood screw. It really tightened the place up. I want to hurry up and get the garage/shop painted and the overhead door installed, but the old board and batten siding needed some tightening up before I pump 20 litres of solid stain on it. And of course the weather has to cooperate. I've given up trying to use acrylic latex because it wants to have +10C (50F) and that just isn't going to happen by the looks of it. So I've gone to solid stain for both siding and trim. I haven't tried to use stain as a trim medium so I am looking forward to seeing how it turns out. I will spend the rest of today putting more caulk on the siding, all the nail holes and anywhere I can see light from the inside but according to the forecast Saturday will be the earliest I can paint. I also need to do some minor carpentry around the beams. If I get going I may be able to start on the tyvek weather wrap today also.

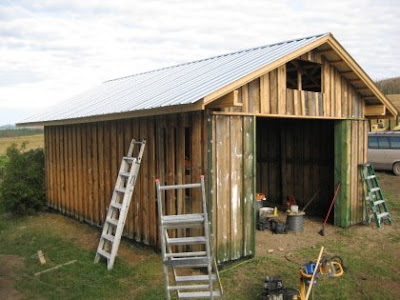

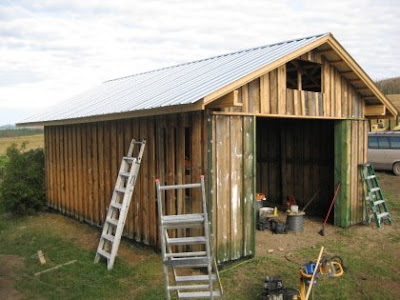

In this photo the green coloured areas are where I have sprayed a copper napthalate wood preservative. The white blotches are a combination of acrylic and polyurathane caulks. What you can't see is the four tubes of brown polyurathane and hundreds of feet of backer rod sealing the board and battens. The open spot next to the ladder leaning up against the side is where the side entry door will go.

This project has been a real learning experience as far as the patience needed to get a good weather proof job. Like anything in life, it seems to be the little things that add up to a successful project. The other thing I have learned is that If I pray for patience, the Big Guy doesn't just give me patience, but plenty of opportunity to practice it. I guess that's the better way. Otherwise after about twenty (O.K maybe more..) prayers I would be walking on water. And that's been done.

Xena enjoying a brush off. That's a very stiff plastic "railway" broom I used to brush the fibers off the side that was left over from the pressure washing. Her pad injury has healed now and she's back to normal.

This is some detail of the "mouse stops" I put on the inside. I will use the same technique, 1/4 inch galvanized mesh, for bird stops at the side soffits. Keeps the critters out but let's the wall "breath".

This is some detail of the "mouse stops" I put on the inside. I will use the same technique, 1/4 inch galvanized mesh, for bird stops at the side soffits. Keeps the critters out but let's the wall "breath".

Had a great sweat last night at Stellaquo. I always enjoy them but the one last night just "hit the spot". It seems to have helped with the congestion from the sans mask spraying of the copper naphthalene and sure left me, as always, mellowed out.

Time to go - I smell a brunch of local eggs and Mennonite sausage..

In this photo the green coloured areas are where I have sprayed a copper napthalate wood preservative. The white blotches are a combination of acrylic and polyurathane caulks. What you can't see is the four tubes of brown polyurathane and hundreds of feet of backer rod sealing the board and battens. The open spot next to the ladder leaning up against the side is where the side entry door will go.

This project has been a real learning experience as far as the patience needed to get a good weather proof job. Like anything in life, it seems to be the little things that add up to a successful project. The other thing I have learned is that If I pray for patience, the Big Guy doesn't just give me patience, but plenty of opportunity to practice it. I guess that's the better way. Otherwise after about twenty (O.K maybe more..) prayers I would be walking on water. And that's been done.

Xena enjoying a brush off. That's a very stiff plastic "railway" broom I used to brush the fibers off the side that was left over from the pressure washing. Her pad injury has healed now and she's back to normal.

This is some detail of the "mouse stops" I put on the inside. I will use the same technique, 1/4 inch galvanized mesh, for bird stops at the side soffits. Keeps the critters out but let's the wall "breath".

This is some detail of the "mouse stops" I put on the inside. I will use the same technique, 1/4 inch galvanized mesh, for bird stops at the side soffits. Keeps the critters out but let's the wall "breath".

Had a great sweat last night at Stellaquo. I always enjoy them but the one last night just "hit the spot". It seems to have helped with the congestion from the sans mask spraying of the copper naphthalene and sure left me, as always, mellowed out.

Time to go - I smell a brunch of local eggs and Mennonite sausage..

Comments